Post by butlersrangers on Mar 12th, 2013 at 2:25am

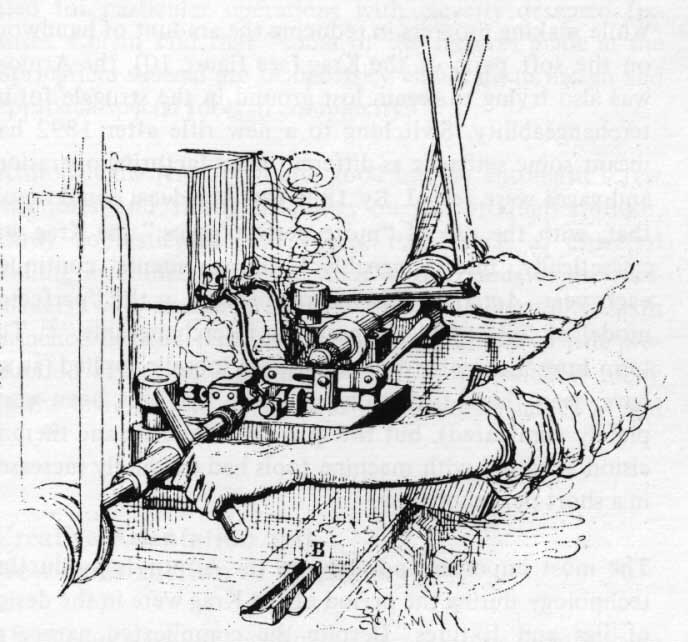

I do not know the actual manufacturing process of Krag barrels. I use to assume the barrel was browned (blued) and the sights installed after it was fitted and head-spaced to the action. This clearly does not seem to be the case. It appears the barrel was fully machined, sight holes drilled and tapped, front sight stud dovetailed/brazed/dressed up, breech notched for extractor and barrel browned, before installation on the action. I do not know at what point barrels were proofed. Also, I wonder if the chamber was 'finish reamed' after assembly to the action? It is evident tolerances were held very close when the Krag was manufactured. If anyone has definitive knowledge or documentation regarding the manufacture and assembly of Krag barrels, many of us would certainly enjoy knowing more about the process. I am attaching some pictures showing minor barrel details. #1 - Index mark

Krag-index-mark.JPG ( 68 KB | 0

Downloads )

Krag-index-mark.JPG ( 68 KB | 0

Downloads )

Krag-index-mark.JPG ( 68 KB | 0

Downloads )

Krag-index-mark.JPG ( 68 KB | 0

Downloads )