Post by butlersrangers on May 10th, 2015 at 11:19pm

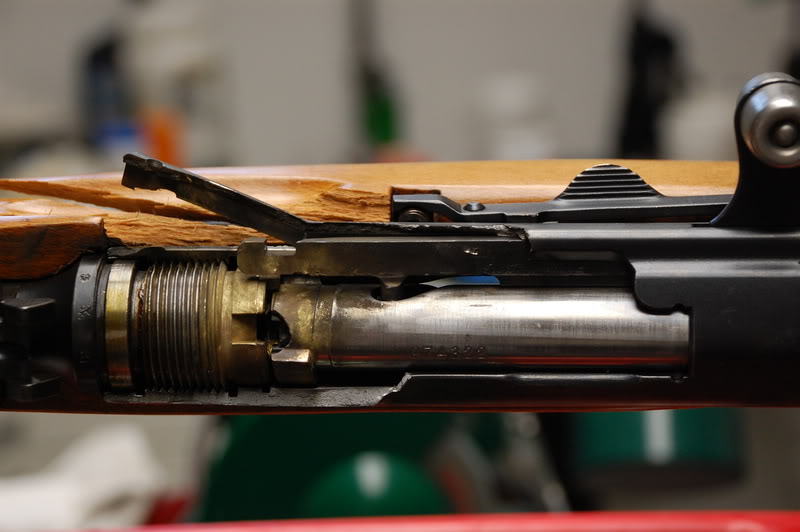

This 'catastrophic failure' of a Norwegian Krag occurred in Great Britain at a practice match in the Spring of 2014. It was investigated by the NRA-UK. The 23 page report was posted today on the Military Surplus Collectors Forum (under Krag rifles).

The Norwegian Krag action (#32513) was of 1897 Steyr vintage. A Norwegian match barrel was installed circa 1950 and the rifle has been in routine use and well maintained. Nicks and alterations to the action receiver ring and threads led to suspicions regarding the installer's competency.

The 'home loads' (reloads) used Norma brass, 140 grain bullet, and 34.4 grains of Accurate 2520. (This load appears just above a 'starting load' and well below Max. in one Accurate Arms table, I found). The rifle came apart on the fourth shot. The 'shooter', a neighboring 'shooter', and a spectator were injured and required hospital treatment (surgery for two and OP for the third).

The NRA-UK report noted 'grossly deformed necks' on some of the 'homeloads', which indicated improper setting of equipment. They displayed one of the fired cases, which looked normal. However, IMHO, the photo of a deformed loaded case in a Wilson gauge, appears to show a possible head-space problem, caused by excessive case length or poor adjustments. (I wish the report gave more attention to the dimensions of the fired cases and case length of the deformed necks).

Some parts of the destroyed Krag-Jogensen could not be found. The NRA-UK found no clear definite cause and called it: "A single overload event". If I understand the report's conclusion correctly, they attributed the failure to an excessive load or latent defect in the re-barreled rifle.

(The excessive pressure could have been an under-load detonation, an excessive pressure over-load, or something related to the 'funny' case necks).

GB-krg0.JPG ( 48 KB | 5

Downloads )

GB-krg0.JPG ( 48 KB | 5

Downloads )

GB-krg1.JPG ( 65 KB | 1

Download )

GB-krg1.JPG ( 65 KB | 1

Download )

GB-krg2.JPG ( 85 KB | 0

Downloads )

GB-krg2.JPG ( 85 KB | 0

Downloads )

GB-krg3.JPG ( 80 KB | 1

Download )

GB-krg3.JPG ( 80 KB | 1

Download )

GB-krg5.JPG ( 62 KB | 1

Download )

GB-krg5.JPG ( 62 KB | 1

Download )

The Norwegian Krag action (#32513) was of 1897 Steyr vintage. A Norwegian match barrel was installed circa 1950 and the rifle has been in routine use and well maintained. Nicks and alterations to the action receiver ring and threads led to suspicions regarding the installer's competency.

The 'home loads' (reloads) used Norma brass, 140 grain bullet, and 34.4 grains of Accurate 2520. (This load appears just above a 'starting load' and well below Max. in one Accurate Arms table, I found). The rifle came apart on the fourth shot. The 'shooter', a neighboring 'shooter', and a spectator were injured and required hospital treatment (surgery for two and OP for the third).

The NRA-UK report noted 'grossly deformed necks' on some of the 'homeloads', which indicated improper setting of equipment. They displayed one of the fired cases, which looked normal. However, IMHO, the photo of a deformed loaded case in a Wilson gauge, appears to show a possible head-space problem, caused by excessive case length or poor adjustments. (I wish the report gave more attention to the dimensions of the fired cases and case length of the deformed necks).

Some parts of the destroyed Krag-Jogensen could not be found. The NRA-UK found no clear definite cause and called it: "A single overload event". If I understand the report's conclusion correctly, they attributed the failure to an excessive load or latent defect in the re-barreled rifle.

(The excessive pressure could have been an under-load detonation, an excessive pressure over-load, or something related to the 'funny' case necks).

GB-krg0.JPG ( 48 KB | 5

Downloads )

GB-krg0.JPG ( 48 KB | 5

Downloads ) GB-krg1.JPG ( 65 KB | 1

Download )

GB-krg1.JPG ( 65 KB | 1

Download ) GB-krg2.JPG ( 85 KB | 0

Downloads )

GB-krg2.JPG ( 85 KB | 0

Downloads ) GB-krg3.JPG ( 80 KB | 1

Download )

GB-krg3.JPG ( 80 KB | 1

Download ) GB-krg5.JPG ( 62 KB | 1

Download )

GB-krg5.JPG ( 62 KB | 1

Download )