Post by FredC on Dec 15th, 2015 at 10:03pm

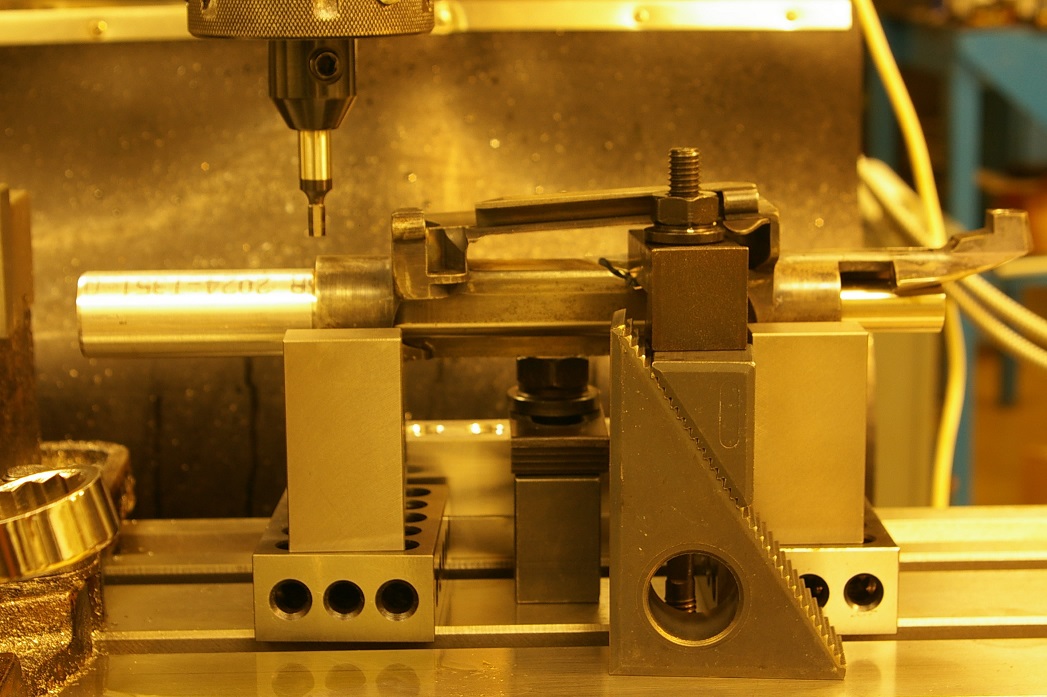

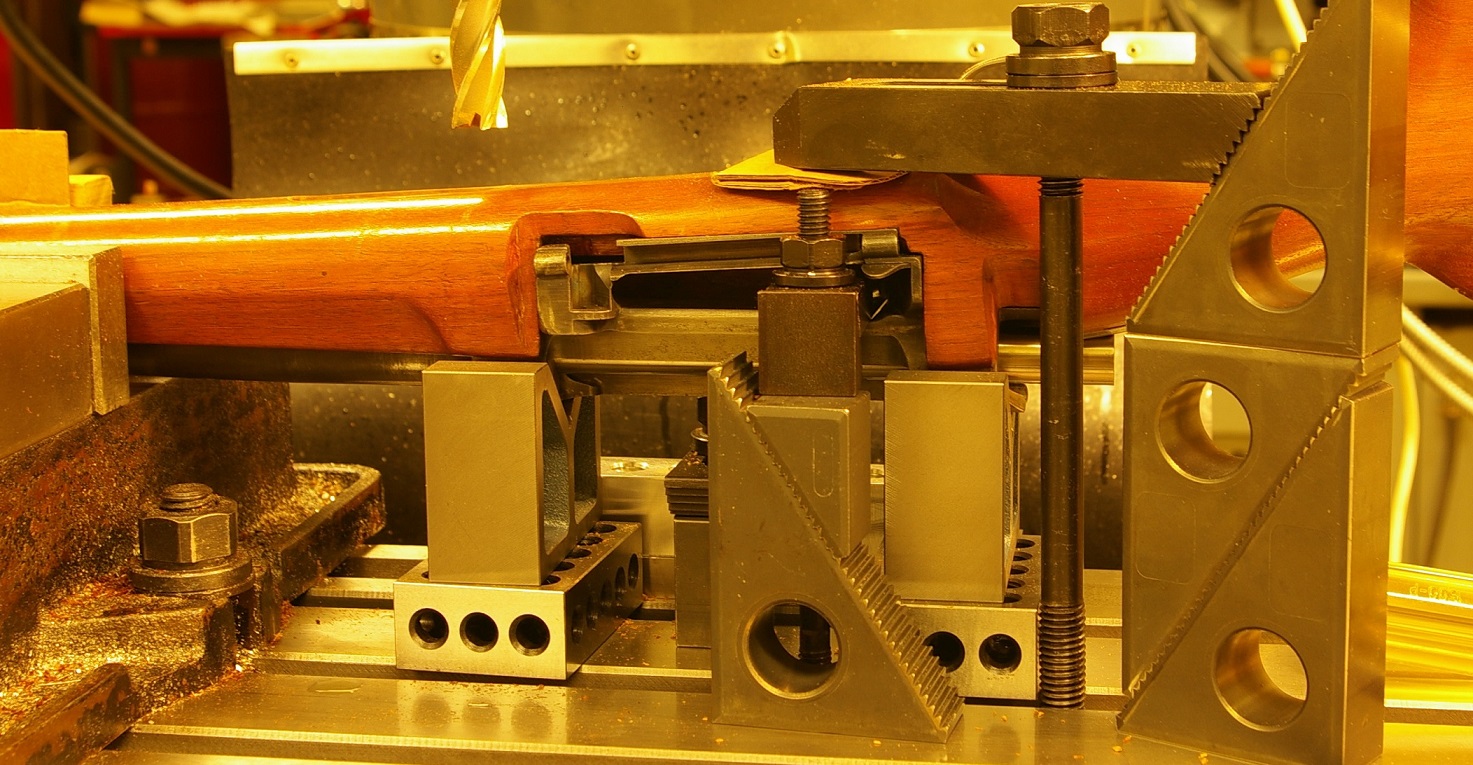

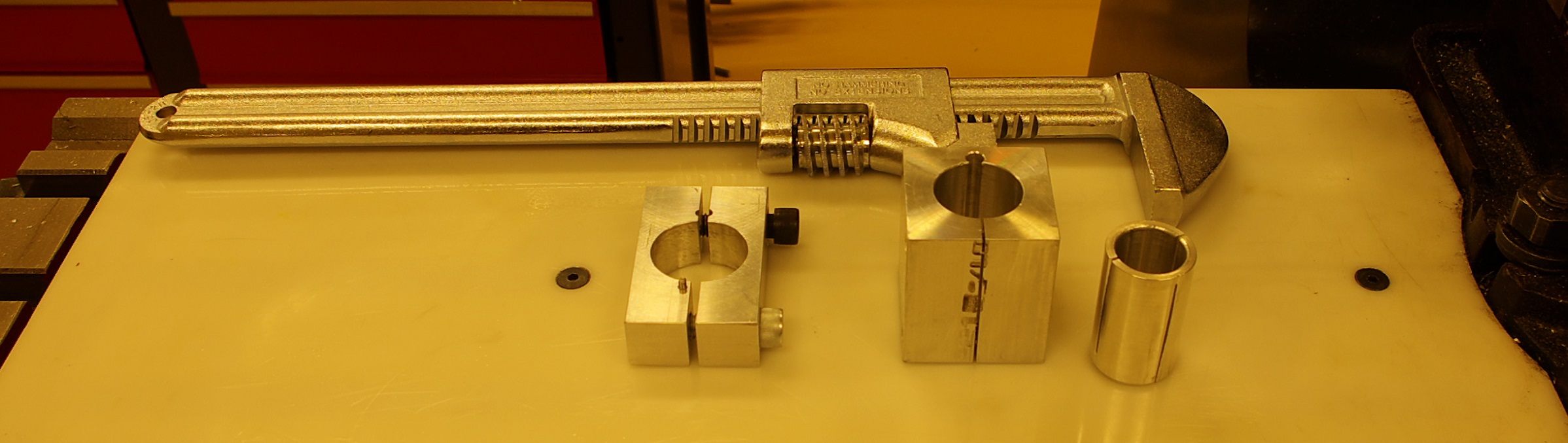

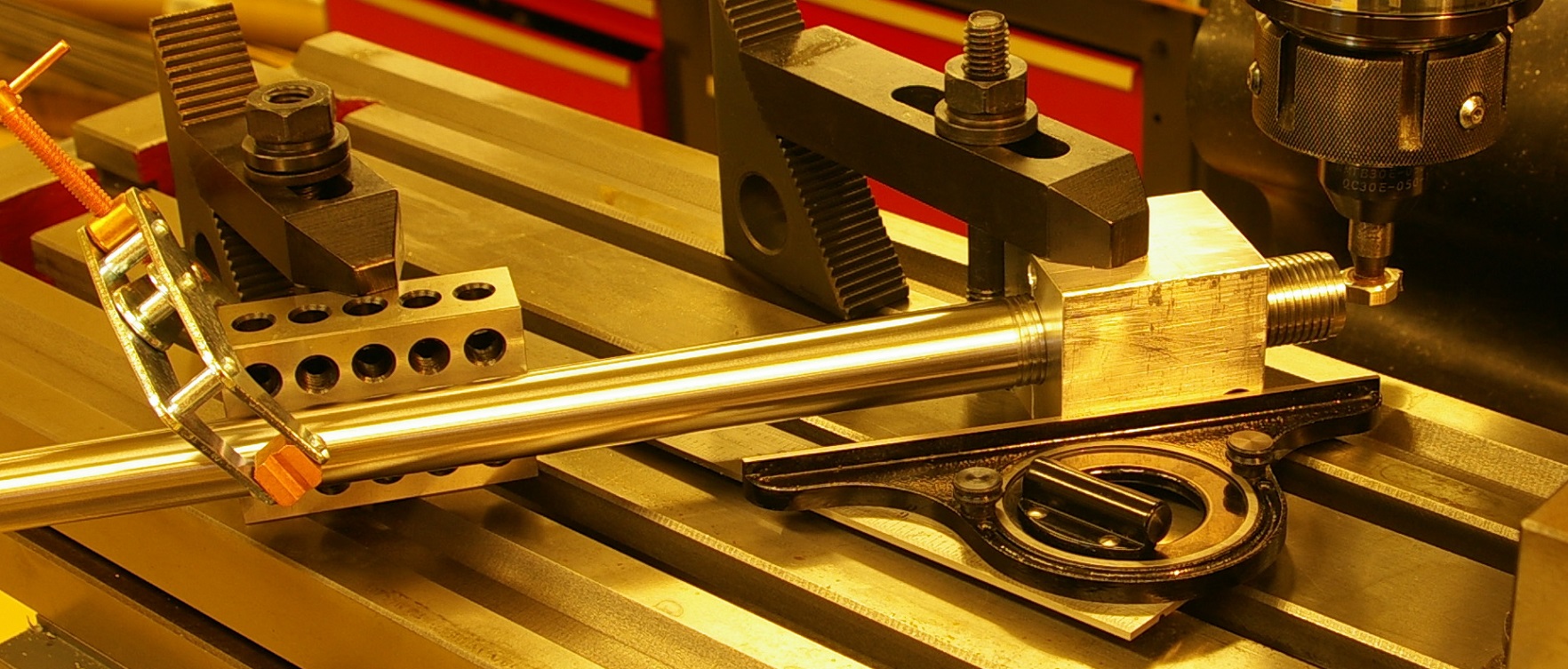

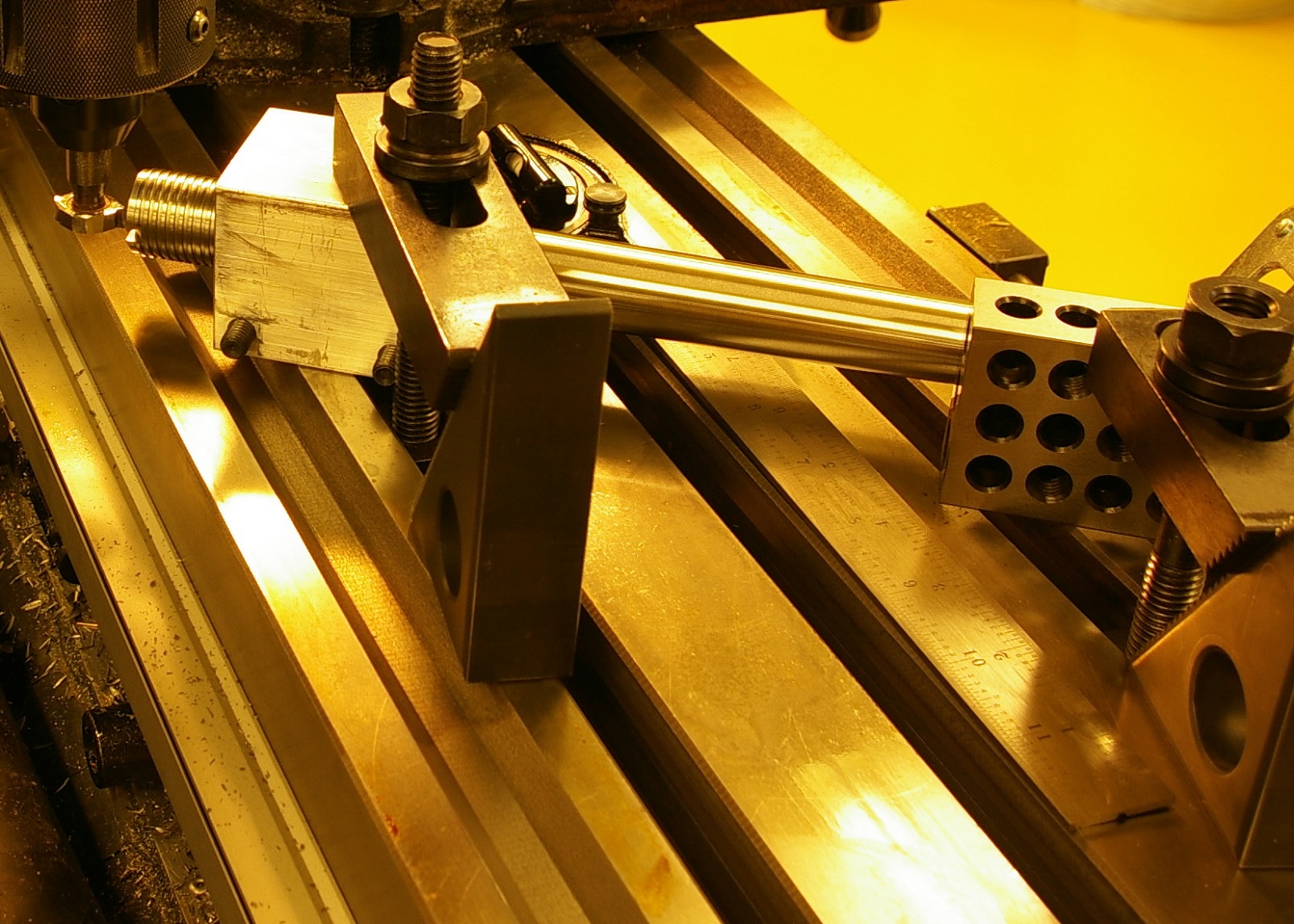

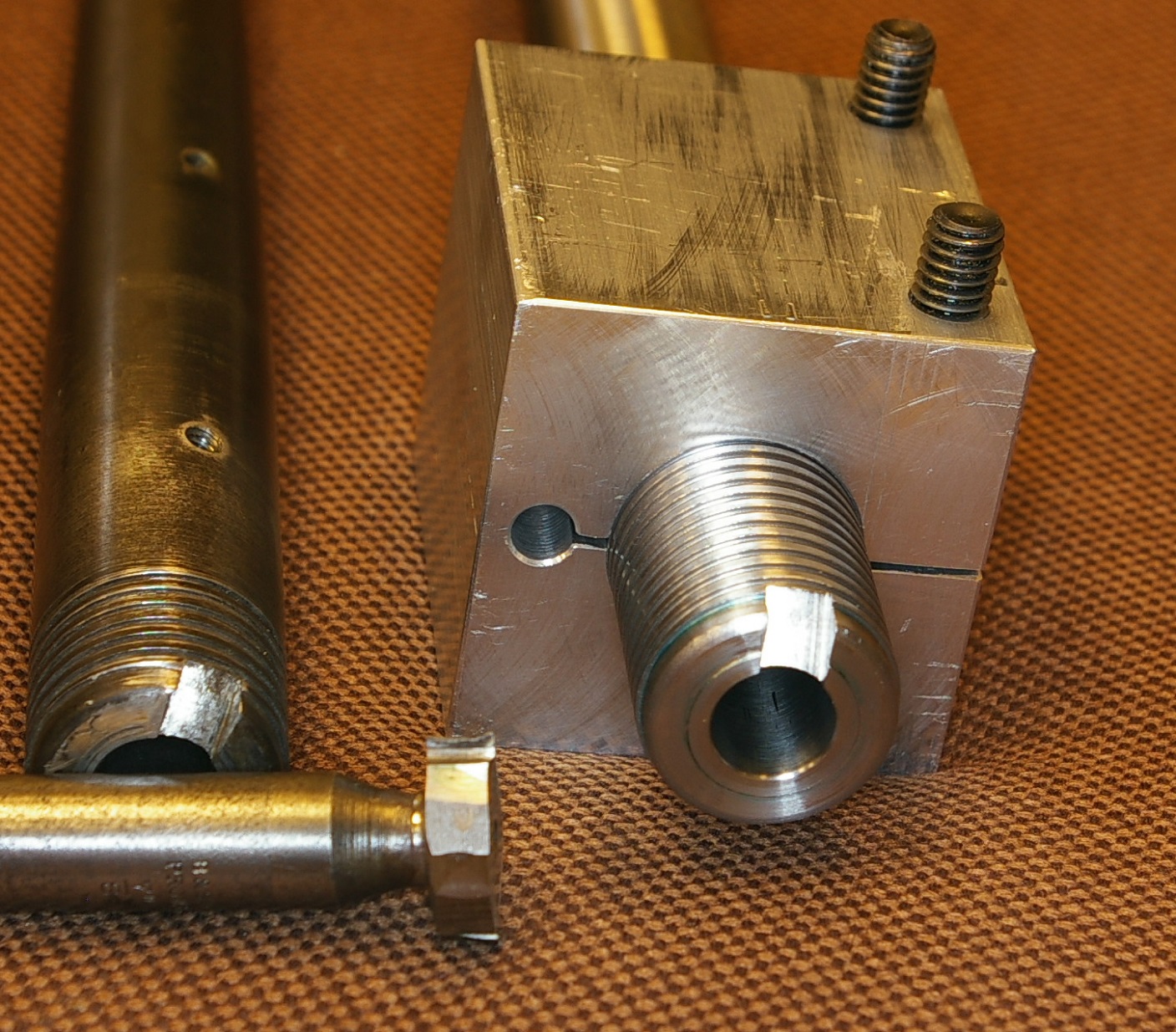

I have no skills as a wood worker or stock maker but have been a machinist for many years. I am trying to attach some photos of a machine set up that others with similar skills might be able to use. If there is an interest in this and posting this stuff is not stepping on toes, I will post more on this project.

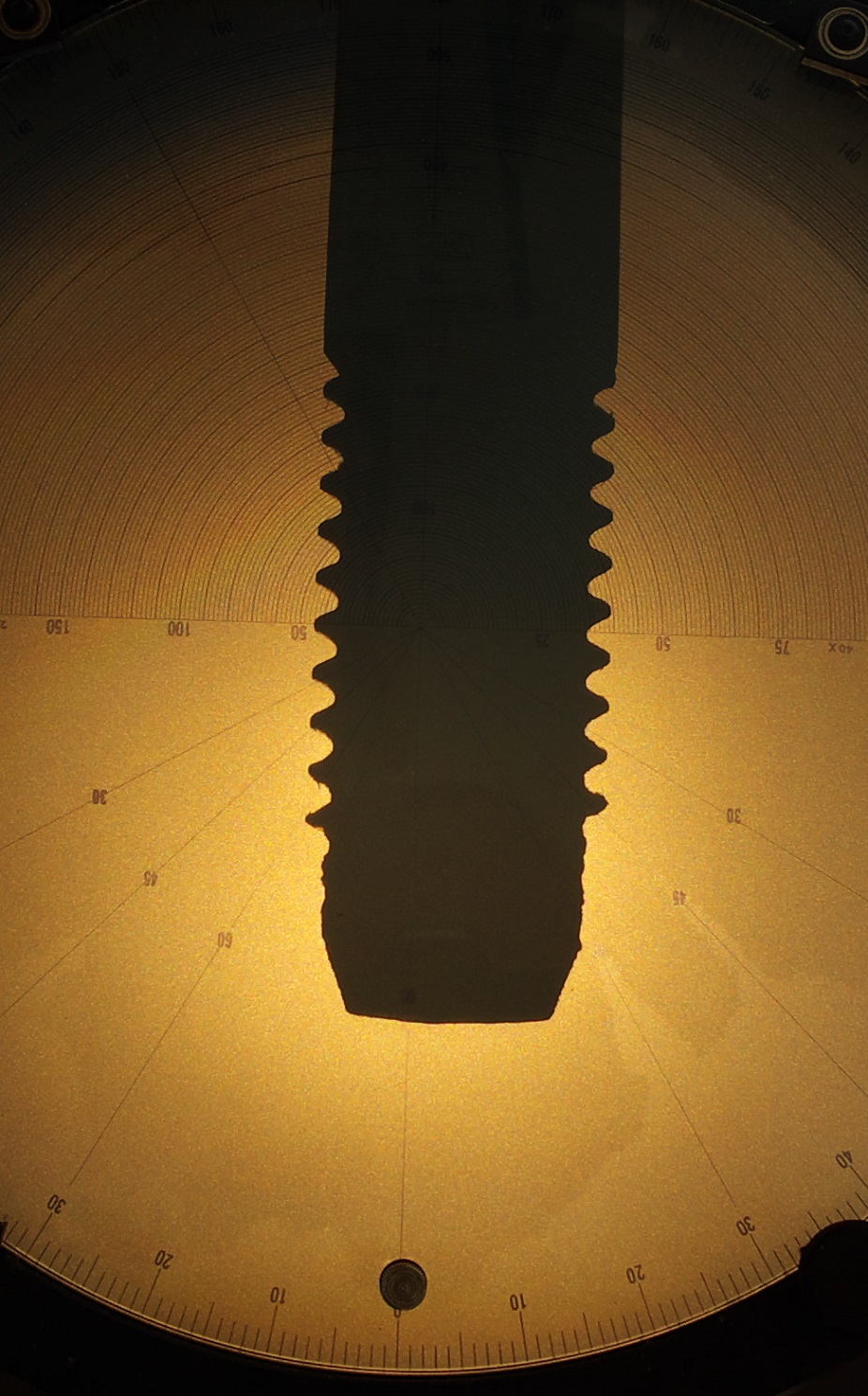

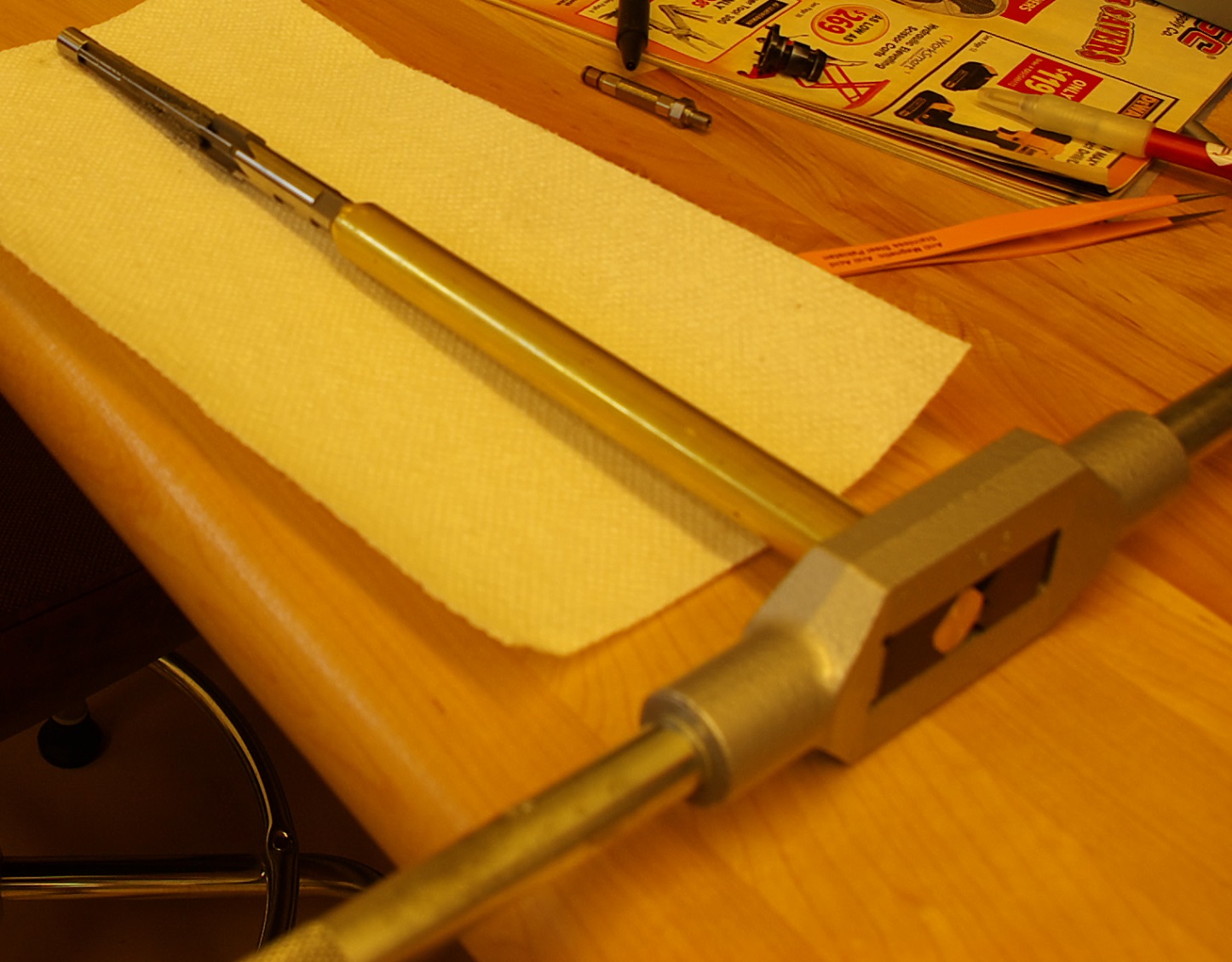

The setup shown is making an accurate hole through the stock for a large pillar that does double duty as a sight mount. This same set up could be used for a small plain pillar to hold down the front of the action when no barrel bands are used on a custom stock. If the photos are really there I will give a description of why and how in the next post.

KragSetupRS.jpg ( 261 KB | 9

Downloads )

KragSetupRS.jpg ( 261 KB | 9

Downloads )

KragMillngStockRS.jpg ( 460 KB | 3

Downloads )

KragMillngStockRS.jpg ( 460 KB | 3

Downloads )

The setup shown is making an accurate hole through the stock for a large pillar that does double duty as a sight mount. This same set up could be used for a small plain pillar to hold down the front of the action when no barrel bands are used on a custom stock. If the photos are really there I will give a description of why and how in the next post.

KragSetupRS.jpg ( 261 KB | 9

Downloads )

KragSetupRS.jpg ( 261 KB | 9

Downloads ) KragMillngStockRS.jpg ( 460 KB | 3

Downloads )

KragMillngStockRS.jpg ( 460 KB | 3

Downloads )