Post by FredC on Dec 18th, 2015 at 6:36pm

After noticing the original screws were ruined I made new ones. For anyone new to Krags they were built before the USA unified screw system was developed. The 2 original are on the left, the middle 2 are the replacements and the 2 on the right are for the front pillar.

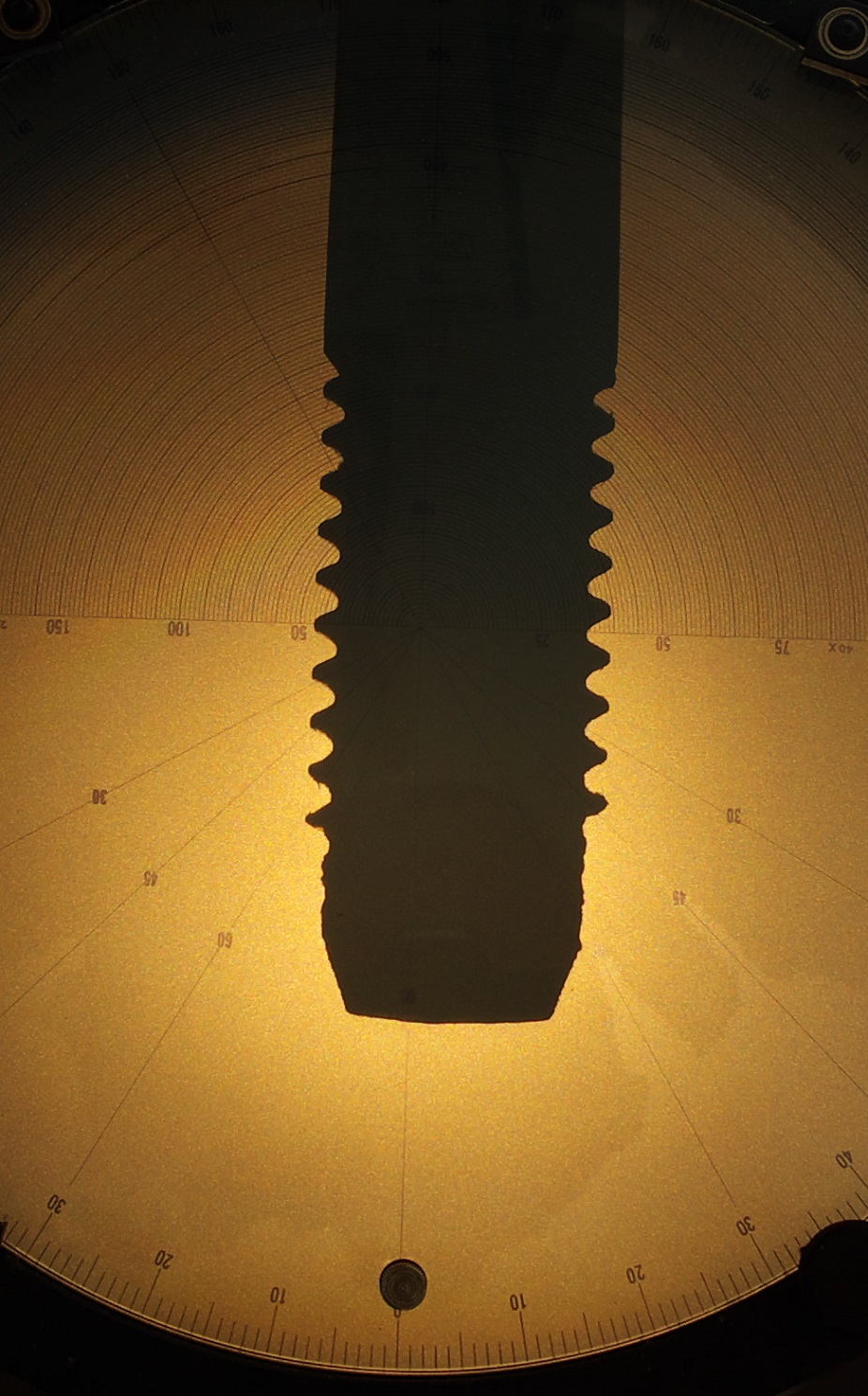

The guard screws are 1/4 in diameter, but with an unusual pitch and thread form. The pitch is 25 compared with 20 and 28 for unc and unf of the unified system. The best I could tell is the Krag screws do have 60 degrees on the flanks as modern unified screws have. I did check the angles on an optical comparator but they were not exact and also worn.

The thread form has unusually large radius at the root and crest of the threads. One could use a standard threading tool and the extra material removed from the roots will have no effect on the fit of a new screw. Making the root radius larger than the standard unified threads will make the screw slightly stronger and make it look to be more original. The peak of a Krag replacement screw has to be filed or machined to near or nearly the correct radius otherwise the screw will bind on the radius or have to be machined so deep the screw will be weakened (see photo).

I made the screws in the photo out of W1 tool steel as it is relatively easy to machine and heat treat. If I did not have an oven or the ability to heat treat I would use Fatigue Proof as it is fairly easy to machine and already heat treated.

I made the 2 guard screws larger than the original on the pitch diameter (checked with wires) and they are still loose because of the tapered threads in the receiver.

At the armory they probably made their own taps and made them oversize to start with as they wore down mostly on the ends and would start to cut a severe taper, so the threads in any one receiver could be slightly oversize and the same size from top to bottom or tapered depending on wear of the tap. Our modern high speed steels (wear resistant) were a gleam in some ones eyes back then.

Screws.jpg ( 466 KB | 1

Download )

Screws.jpg ( 466 KB | 1

Download )

KragScrewDetailrs.jpg ( 388 KB | 2

Downloads )

KragScrewDetailrs.jpg ( 388 KB | 2

Downloads )

The guard screws are 1/4 in diameter, but with an unusual pitch and thread form. The pitch is 25 compared with 20 and 28 for unc and unf of the unified system. The best I could tell is the Krag screws do have 60 degrees on the flanks as modern unified screws have. I did check the angles on an optical comparator but they were not exact and also worn.

The thread form has unusually large radius at the root and crest of the threads. One could use a standard threading tool and the extra material removed from the roots will have no effect on the fit of a new screw. Making the root radius larger than the standard unified threads will make the screw slightly stronger and make it look to be more original. The peak of a Krag replacement screw has to be filed or machined to near or nearly the correct radius otherwise the screw will bind on the radius or have to be machined so deep the screw will be weakened (see photo).

I made the screws in the photo out of W1 tool steel as it is relatively easy to machine and heat treat. If I did not have an oven or the ability to heat treat I would use Fatigue Proof as it is fairly easy to machine and already heat treated.

I made the 2 guard screws larger than the original on the pitch diameter (checked with wires) and they are still loose because of the tapered threads in the receiver.

At the armory they probably made their own taps and made them oversize to start with as they wore down mostly on the ends and would start to cut a severe taper, so the threads in any one receiver could be slightly oversize and the same size from top to bottom or tapered depending on wear of the tap. Our modern high speed steels (wear resistant) were a gleam in some ones eyes back then.

Screws.jpg ( 466 KB | 1

Download )

Screws.jpg ( 466 KB | 1

Download ) KragScrewDetailrs.jpg ( 388 KB | 2

Downloads )

KragScrewDetailrs.jpg ( 388 KB | 2

Downloads )