Post by butlersrangers on Oct 25th, 2016 at 10:05pm

Not Guilty! (IIRC - But, I have mentioned part finishes in the past).

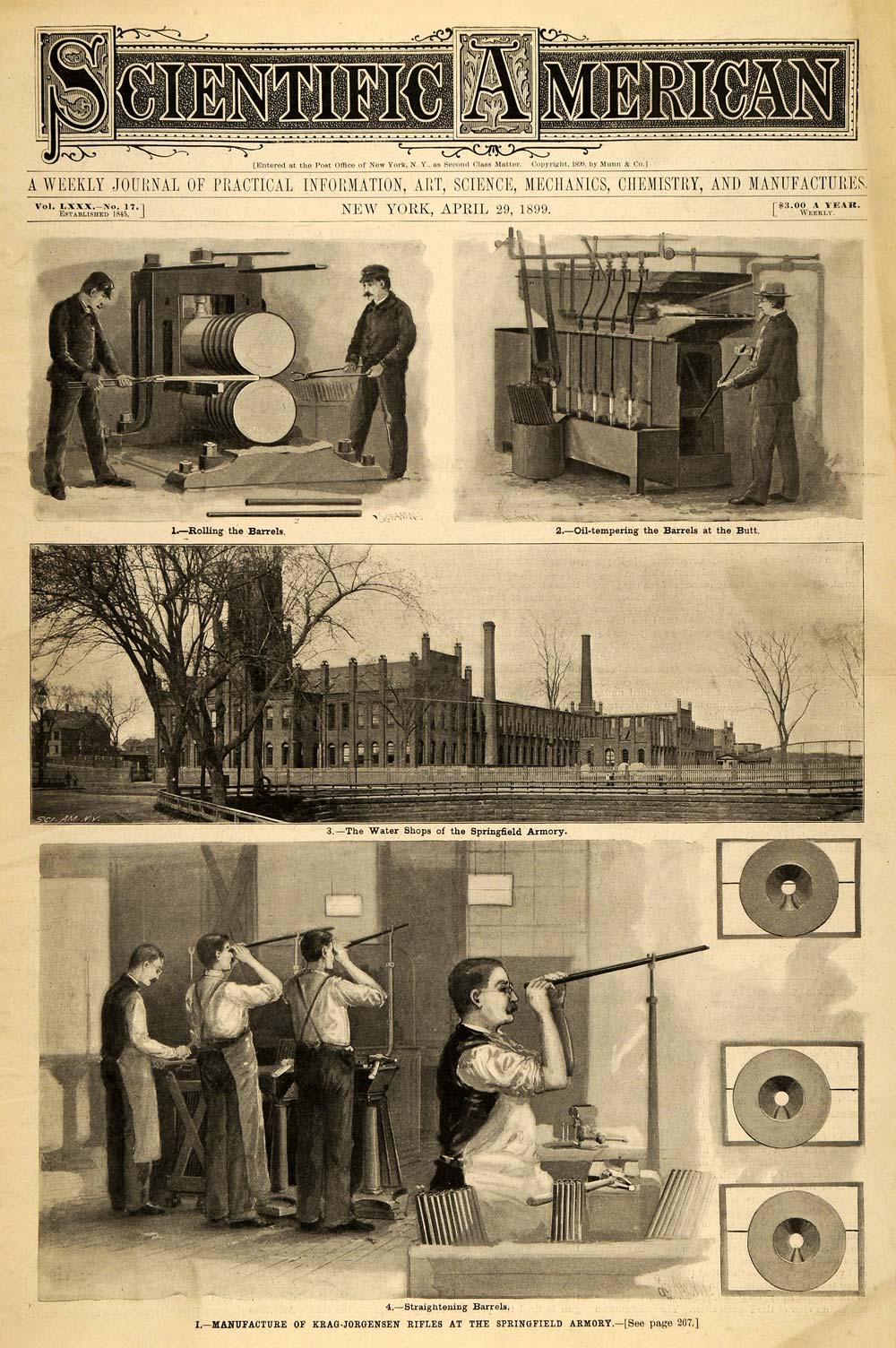

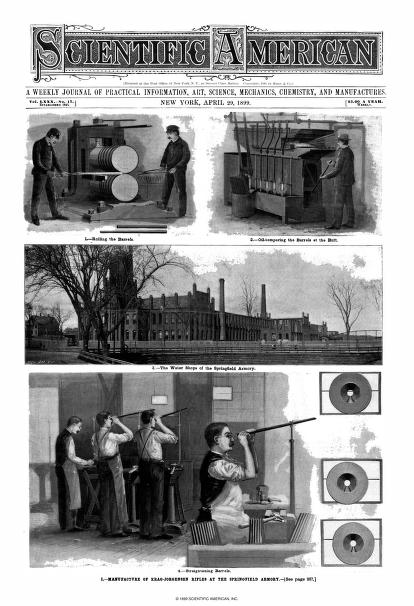

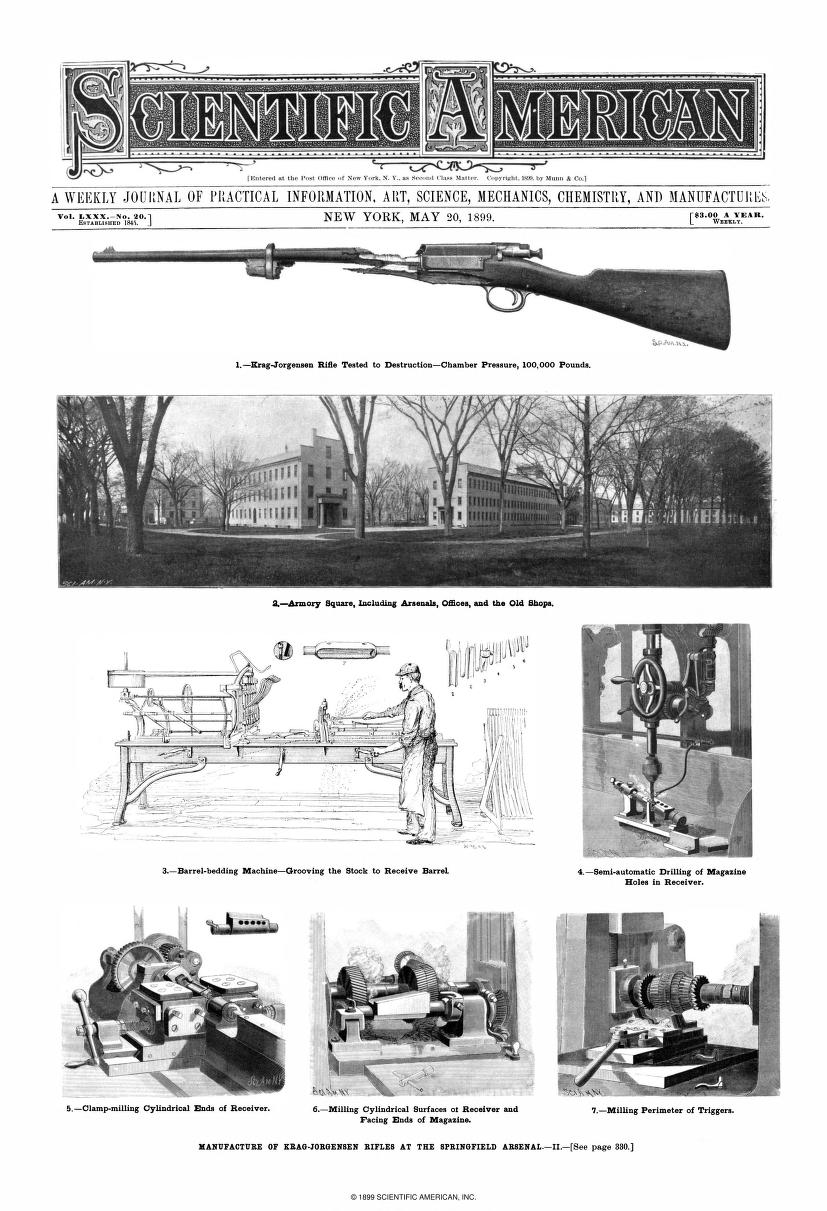

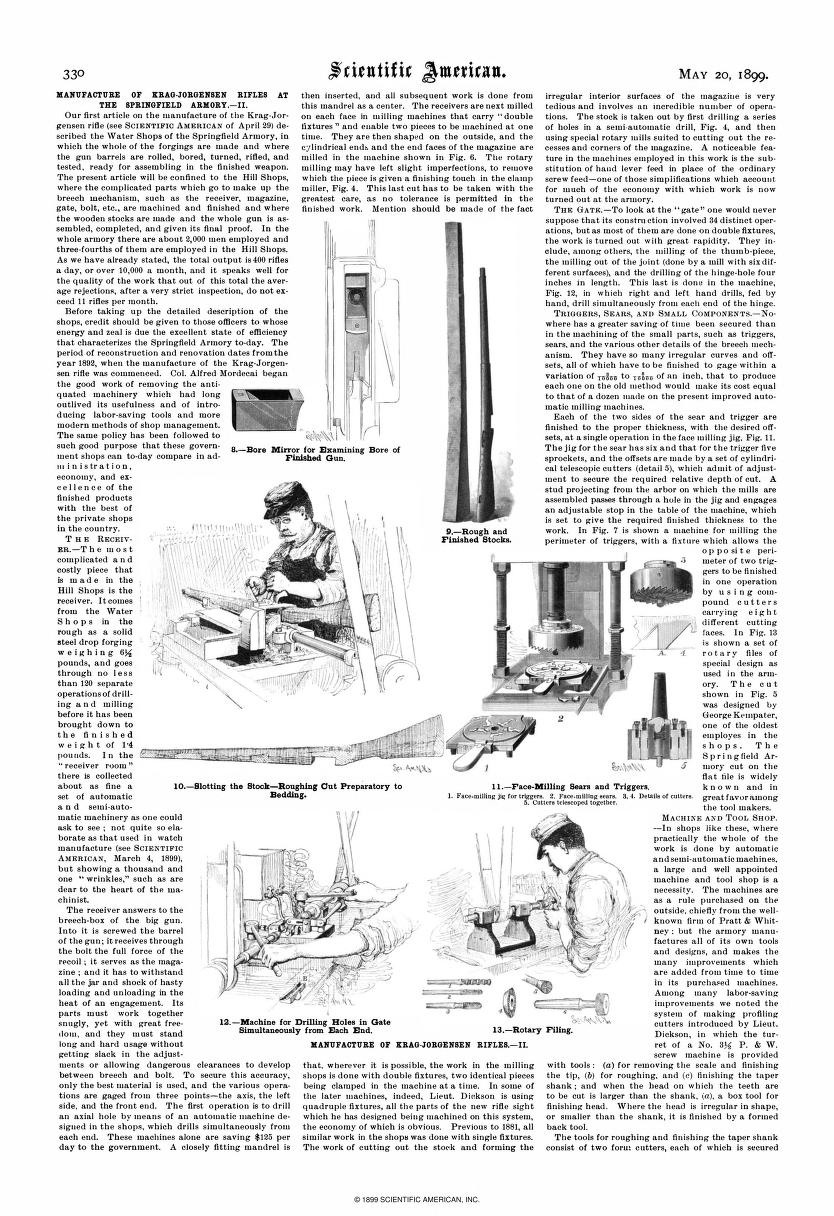

The Casehardening and Tempering of the Krag's 'working parts' was described in "Scientific American" in April and May, 1899. (In fact, the two magazine articles went into most aspects of the manufacture of the Krag at Springfield).

The original articles are featured in Mallory's, "The Krag Rifle Story".

IIRC - The "Scientific American" articles are viewable online.

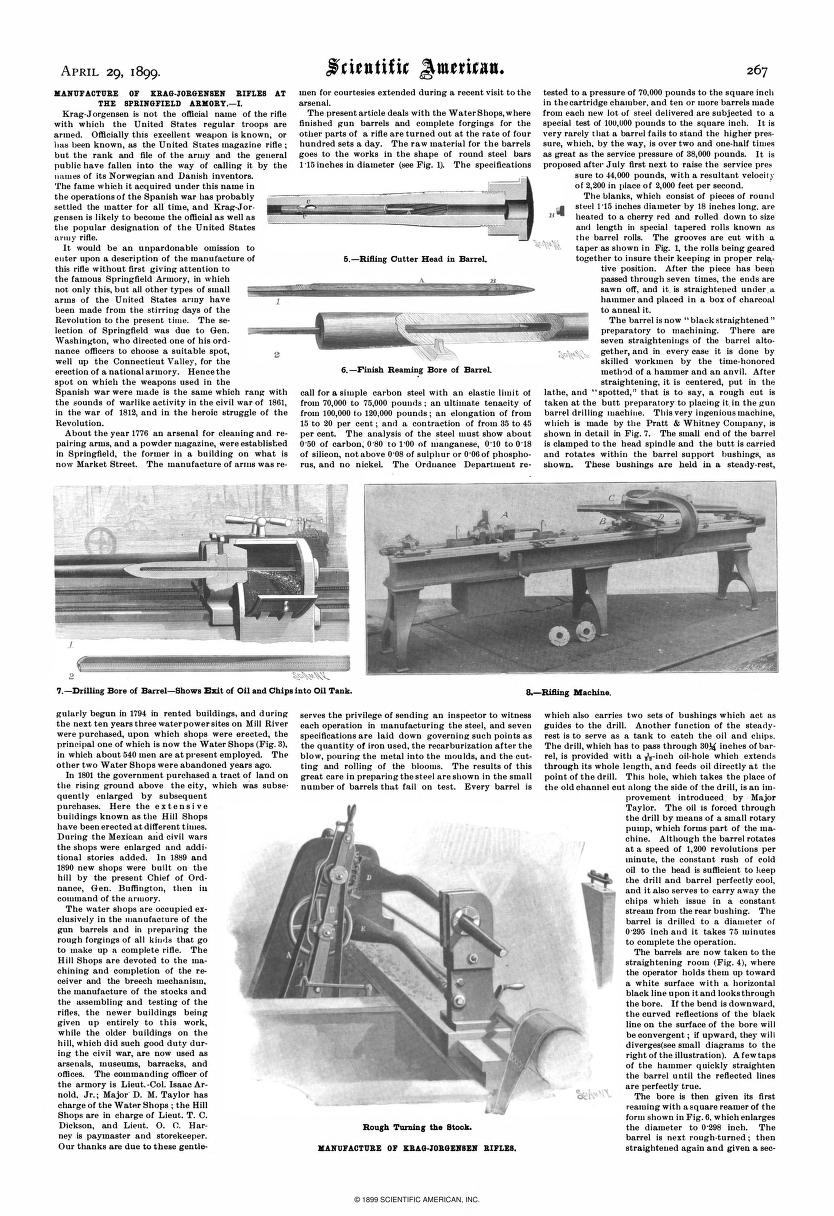

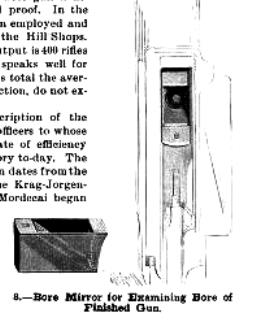

The article(s) do mention "a little cyanide of potassium" being placed on the bolt's lug to give it "special hardness".

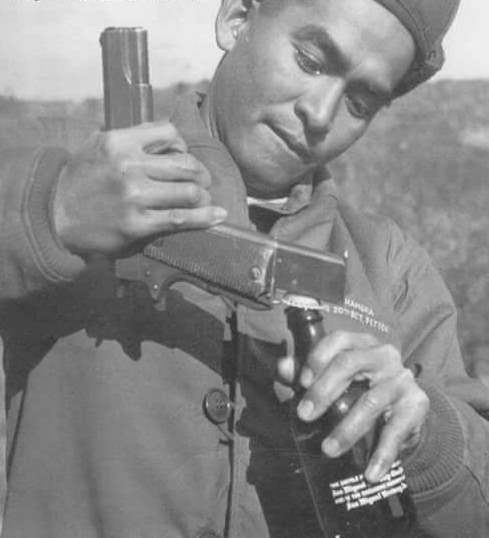

Attached is the relevant description:

IMG_6260.JPG ( 125 KB | 0

Downloads )

IMG_6260.JPG ( 125 KB | 0

Downloads )

The Casehardening and Tempering of the Krag's 'working parts' was described in "Scientific American" in April and May, 1899. (In fact, the two magazine articles went into most aspects of the manufacture of the Krag at Springfield).

The original articles are featured in Mallory's, "The Krag Rifle Story".

IIRC - The "Scientific American" articles are viewable online.

The article(s) do mention "a little cyanide of potassium" being placed on the bolt's lug to give it "special hardness".

Attached is the relevant description:

IMG_6260.JPG ( 125 KB | 0

Downloads )

IMG_6260.JPG ( 125 KB | 0

Downloads )