Post by butlersrangers on Nov 2nd, 2017 at 6:48am

The process as I understand it:

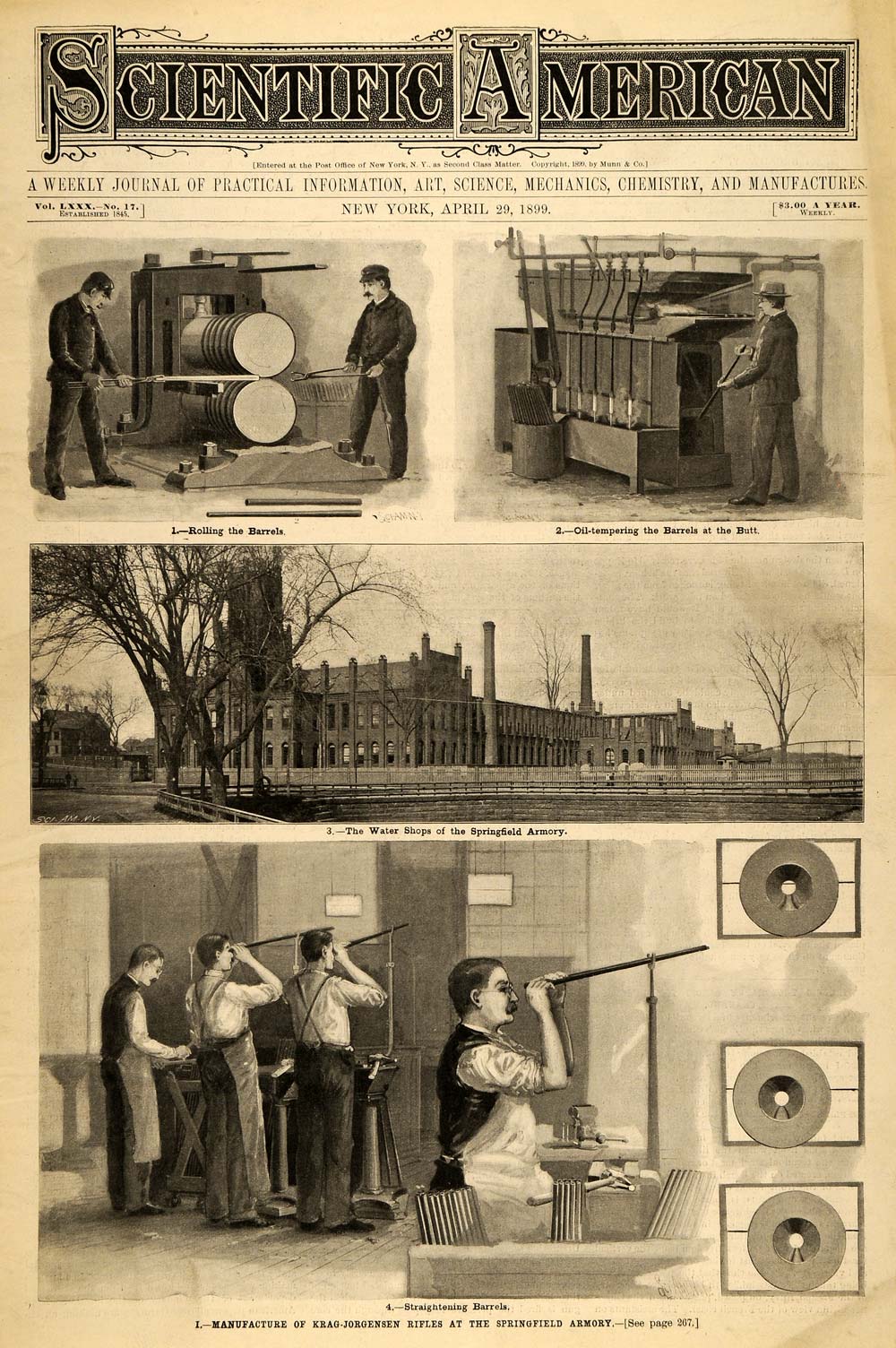

U.S. Krag barrels underwent all manufacturing, threading, proofing, rifling, and browning (bluing) operations at the Springfield Armory 'Water Shops'. It was a very labor intensive process!

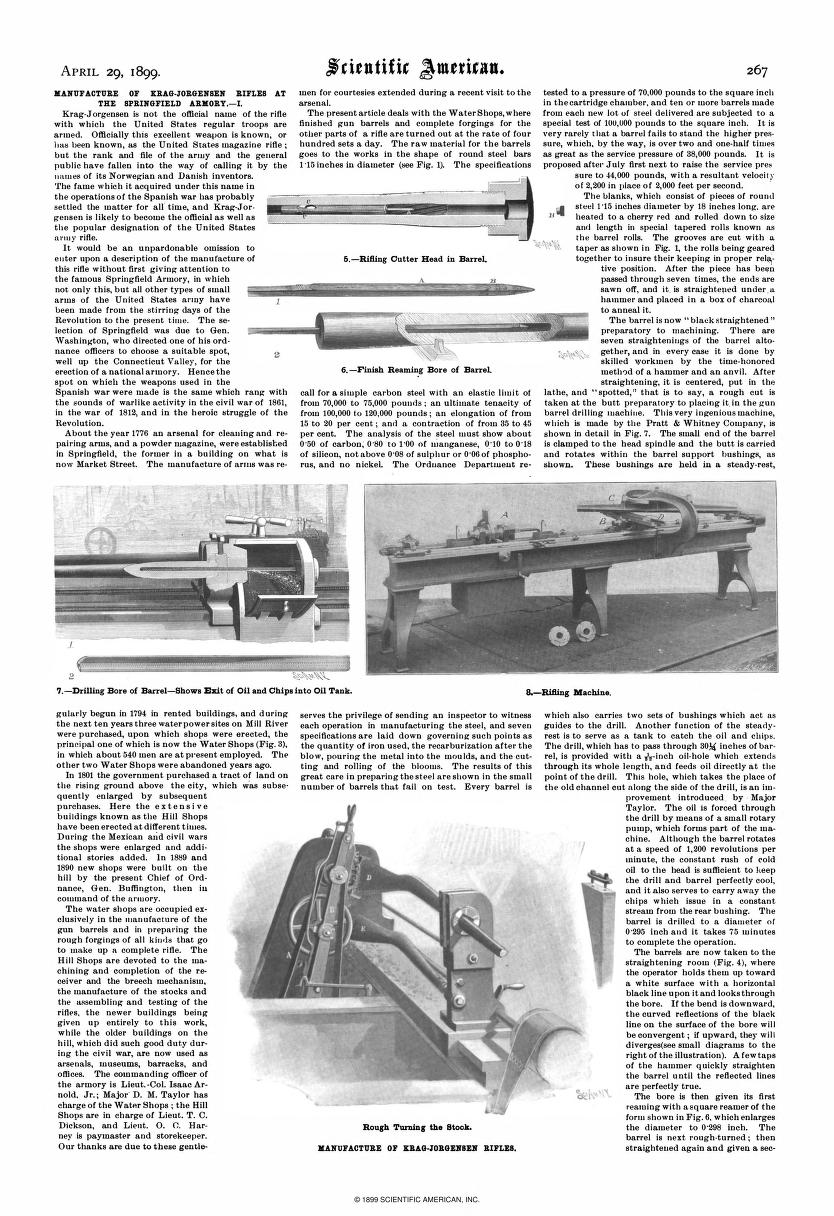

The rifling was done on 28 machines (18 old ones, that had been in use for over 40 years, and 10 new Pratt & Whitney machines).

I believe the Pratt & Whitney machines used dual cutters, cutting two opposite grooves at a time. The grooves were deepened, to a final depth of .04", as an internal tapered rod advanced the cutters on repeat passes. (I am not sure if the older machines worked the same way).

The barrels were proofed, prior to rifling, by boring (reaming) them to .298", cutting action threads and a specialized/temporary 7/16" diameter (.4375") 'straight-walled' chamber.

The Proof Cartridges had different dimensions than the .30-40 Service cartridge. A .294" projectile was used and the powder charge developed 70,000 psi.

Prior to 1897, the proof cartridge was tapered and without bottle-neck. The cartridge had wads to retain its smokeless powder charge. A loose RN lead bullet was loaded directly into the bore, in front of the cartridge case.

In 1897, a self-contained 'bottle-neck' proof cartridge was adopted with a 220 grain jacketed service bullet swagged to .294" diameter.

(I do not fully understand how this bottle-neck proof cartridge was utilized or altered the 'proof process'. Possibly, the preliminary proof process stayed the same and the 1897 Proof Cartridge was used to test a small percentage of completely finished arms)?

When totally finished, the Krag barrels were sent to the Hill Shops, where they ultimately were screwed into completed Receivers.

The Receivers were machined at the Hill Shops (from 6 1/2 pound Water Shop forgings), heat treated, and assembled, prior to barrels, with 'timed threads' being installed.

ScAm-1_002.jpg ( 288 KB | 5

Downloads )

ScAm-1_002.jpg ( 288 KB | 5

Downloads )

ScAm-1-267_001.jpg ( 240 KB | 3

Downloads )

ScAm-1-267_001.jpg ( 240 KB | 3

Downloads )

ScAm-1-268_002.jpg ( 255 KB | 3

Downloads )

ScAm-1-268_002.jpg ( 255 KB | 3

Downloads )

U.S. Krag barrels underwent all manufacturing, threading, proofing, rifling, and browning (bluing) operations at the Springfield Armory 'Water Shops'. It was a very labor intensive process!

The rifling was done on 28 machines (18 old ones, that had been in use for over 40 years, and 10 new Pratt & Whitney machines).

I believe the Pratt & Whitney machines used dual cutters, cutting two opposite grooves at a time. The grooves were deepened, to a final depth of .04", as an internal tapered rod advanced the cutters on repeat passes. (I am not sure if the older machines worked the same way).

The barrels were proofed, prior to rifling, by boring (reaming) them to .298", cutting action threads and a specialized/temporary 7/16" diameter (.4375") 'straight-walled' chamber.

The Proof Cartridges had different dimensions than the .30-40 Service cartridge. A .294" projectile was used and the powder charge developed 70,000 psi.

Prior to 1897, the proof cartridge was tapered and without bottle-neck. The cartridge had wads to retain its smokeless powder charge. A loose RN lead bullet was loaded directly into the bore, in front of the cartridge case.

In 1897, a self-contained 'bottle-neck' proof cartridge was adopted with a 220 grain jacketed service bullet swagged to .294" diameter.

(I do not fully understand how this bottle-neck proof cartridge was utilized or altered the 'proof process'. Possibly, the preliminary proof process stayed the same and the 1897 Proof Cartridge was used to test a small percentage of completely finished arms)?

When totally finished, the Krag barrels were sent to the Hill Shops, where they ultimately were screwed into completed Receivers.

The Receivers were machined at the Hill Shops (from 6 1/2 pound Water Shop forgings), heat treated, and assembled, prior to barrels, with 'timed threads' being installed.

ScAm-1_002.jpg ( 288 KB | 5

Downloads )

ScAm-1_002.jpg ( 288 KB | 5

Downloads ) ScAm-1-267_001.jpg ( 240 KB | 3

Downloads )

ScAm-1-267_001.jpg ( 240 KB | 3

Downloads ) ScAm-1-268_002.jpg ( 255 KB | 3

Downloads )

ScAm-1-268_002.jpg ( 255 KB | 3

Downloads )