Post by milsurpshooter on Feb 26th, 2018 at 6:43pm

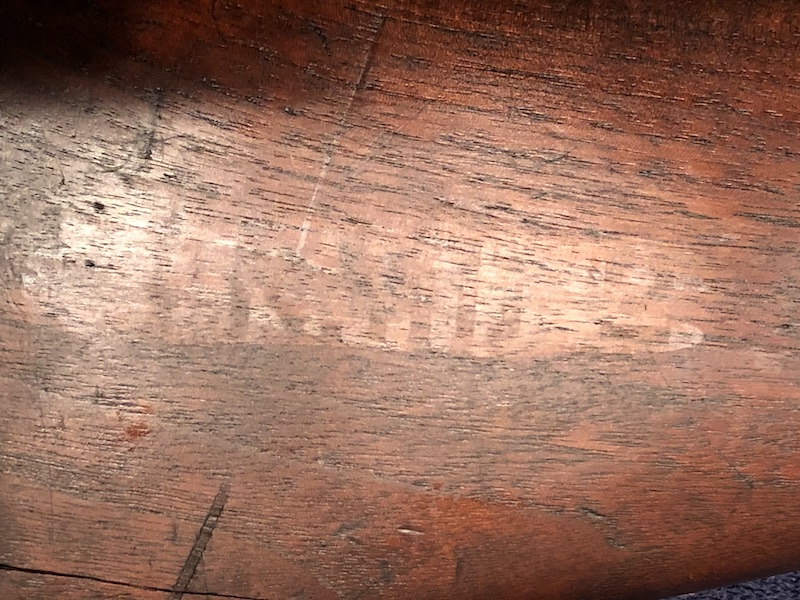

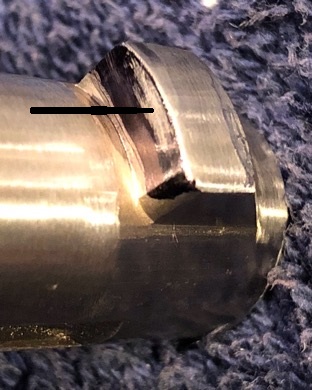

My sporterized Krag is very similar to one that was just posted about in a different thread a few days ago. Hopefully the pics will show up as attachments (I will add better pics once it's cleaned up). I will need to add a front sight and replace the bolt which has had the firing pin tip cut and bolt face welded. Other than a small crack in the heel of the stock and a generous amount of patina, I found it to be in rather great shape.

Some initial questions....

1. Did Krag front sights fit into a dovetail cut on the barrel or were they just silver soldered/brazed onto the barrel contour?

2. Should a new bolt need to be fitted in order to headspace correctly? Can I use my Brit .303 headspace gauges to check for proper fit?

Thank you in advance,

- milsurpshooter

IMG_5162.PNG ( 51 KB | 3

Downloads )

IMG_5162.PNG ( 51 KB | 3

Downloads )

IMG_5174.PNG ( 86 KB | 1

Download )

IMG_5174.PNG ( 86 KB | 1

Download )

Some initial questions....

1. Did Krag front sights fit into a dovetail cut on the barrel or were they just silver soldered/brazed onto the barrel contour?

2. Should a new bolt need to be fitted in order to headspace correctly? Can I use my Brit .303 headspace gauges to check for proper fit?

Thank you in advance,

- milsurpshooter

IMG_5162.PNG ( 51 KB | 3

Downloads )

IMG_5162.PNG ( 51 KB | 3

Downloads ) IMG_5174.PNG ( 86 KB | 1

Download )

IMG_5174.PNG ( 86 KB | 1

Download )