Post by Zgun on Mar 26th, 2019 at 3:57pm

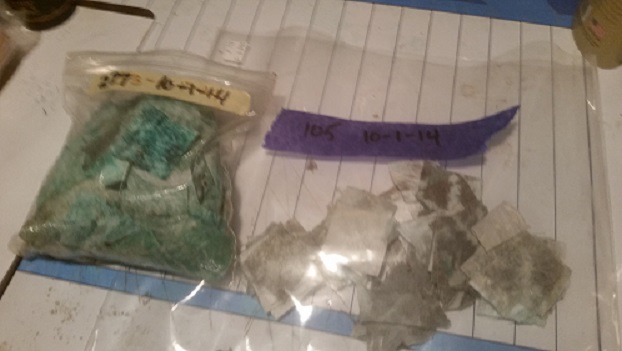

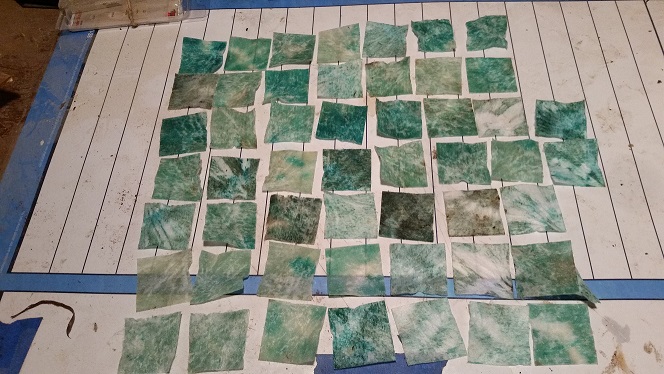

A great thread, with well thought out solutions from experience. I have a Remington 1903A3 manufactured in 1943. It has been in my family since the 50's. When I became the custodian it shot well but the end of the bore looked like it had no rifling. Inspection with a loupe indicated the groves were filled with copper/gliding metal. 829 patches later with Hoppes #9 and judicious use of a bronze brush the bore was clean but not shiny, most likely due to the corrosive ammo that was in use in the 40's and into the 50's. It took a month to remove all of the layers of powder fouling and copper/gliding metal. I soaked it over night in Hoppes and then hit it with the brush and clean patches until they came out white. I did that virtually every day for a month until most all of the powder fouling/carbon and all metal fouling was gone. It shoots well and cleans much better now when it does get shot. A labor of love, but worth it.

Zgun

03_cleaning_382_patches_R1.jpg ( 58 KB | 0

Downloads )

03_cleaning_382_patches_R1.jpg ( 58 KB | 0

Downloads )

03_cleaning_447_patches_R1.jpg ( 90 KB | 0

Downloads )

03_cleaning_447_patches_R1.jpg ( 90 KB | 0

Downloads )

03_cleaning-copper_on_patches_R1.jpg ( 130 KB | 0

Downloads )

03_cleaning-copper_on_patches_R1.jpg ( 130 KB | 0

Downloads )

Zgun

03_cleaning_382_patches_R1.jpg ( 58 KB | 0

Downloads )

03_cleaning_382_patches_R1.jpg ( 58 KB | 0

Downloads ) 03_cleaning_447_patches_R1.jpg ( 90 KB | 0

Downloads )

03_cleaning_447_patches_R1.jpg ( 90 KB | 0

Downloads ) 03_cleaning-copper_on_patches_R1.jpg ( 130 KB | 0

Downloads )

03_cleaning-copper_on_patches_R1.jpg ( 130 KB | 0

Downloads )